The OpenLung Emergency Medical Ventilator (OEMV) is a stopgap solution to the global shortage of medical ventilators. Its rapid development is the result of a novel open source paradigm that allows team members to make real-time contributions from any place in the world. DevOps is overseen by a cabal of professionals whom separate the wheat from the chaff and direct the collective effort. The device itself is composed of widely available materials and put together via simple fabrication processes. Electrical components and software have also been developed, these allow basic parameters and controls to be set by clinicians. Physical working prototypes have been built and testing toward a final product is well underway. The OEMV is an open piece of technology that can be manufactured and deployed anywhere in the world.

Partners

The project has been organized and published on GitLab, a software repository system that enables us to be an effective operational force.

Link to Repository

We have worked in close collaboration with Open Source Ventilator Ireland.

Check them out here

Any medical device must be tested and approved for use with real patients, that is why we have been openly collaborating with many healthcare professionals.

Learn more

There is a massive shortfall of medical ventilators throughout both the developed and developing world. Even with the promise of a vastly increased production capacity on the horizon; projected demand will not be met. In short, there is desperate need for an immediate stopgap solution. With this in mind the retrofitting of readily available devices via the development of cost-effective components—these things brought together via an easily replicated fabrication process—is beyond promising.

The MIT Emergency Ventilator (E-Vent) Project has inspired our own initiatives and provided firm guidance regarding technical specifications and quality control. By using online based DevOps tools (e.g. GitLab) we have been able to work around the clock and coordinate the efforts of qualified people from all over the world. Although our project is an open sourced initiative, all final efforts are rigorously overseen by a dedicated team of both medical and engineering professionals. Our aim is to set as many capable minds as possible toward a common goal—the development and subsequent deployment of a functional medical device to aid in the recovery of those afflicted with COVID-19.

Our focus developed along the line of retrofitting parts that are easily manufactured and maintain a high degree of standing availability (e.g. manual resuscitators). We drew inspiration from their rudimentary design but developed attributes that would use more robust, but also readily available, materials. Most of the components in our finalised design are novel, but we've made sure that the materials from which they are manufactured are common and widely available through numerous supply chains. If suggested materials should become scarce or unavailable—in a given country or region—there are alternative materials that may be used (we've accounted for this within our design). Further, all components are easily manufactured via common methods (i.e. CNC/Laser/Water Jet Cutting, High Volume Stamping, etc.). The OpenLung Emergency Medical Ventilator may be built using near at hand materials through simple fabrication processes.

The electrical hardware of the OpenLung consists of components that are as accessible as the materials which comprise its mechanical components. Software has been developed for the manual operation of standard controls (i.e. Respiratory Rate, Inspiratory/Expiration Ration, Tidal Volume) and to provide real-time readouts (i.e. Peek, Plateau, and Positive End-Expiratory Pressure). Also, an automated alarm system has been incorporated and will alert nearby clinician(s) should hardware fail or control adjustments need be made. Both mechanical and non-mechanical aspects of OpenLung have moved beyond proof-of-principle and into active physical trials.

Due to OpenLung's unique open source development process we've been able to progress through numerous paper-prototype iterations with great rapidity; this accelerated pace has allowed us to move from drawing board to physical model in only two short weeks. The ongoing testing of working prototypes has helped us improve upon and simplify mechanical components as results are fed back into the OpenLung community for group driven analysis. We are rapidly advancing toward a finalised model.

OpenLung's open source development paradigm has unleashed the creative potential and technological knowhow of hundreds of people across the world. Their collective efforts have been harnessed and driven toward the completion of a medical device that is easily built and available for widespread use. As the COVID-19 pandemic escalates so too does necessity of having essential equipment available to medical professionals. The rapid development and deployment of the OpenLung Emergency Medical Ventilator provides a solution that will surely save lives.

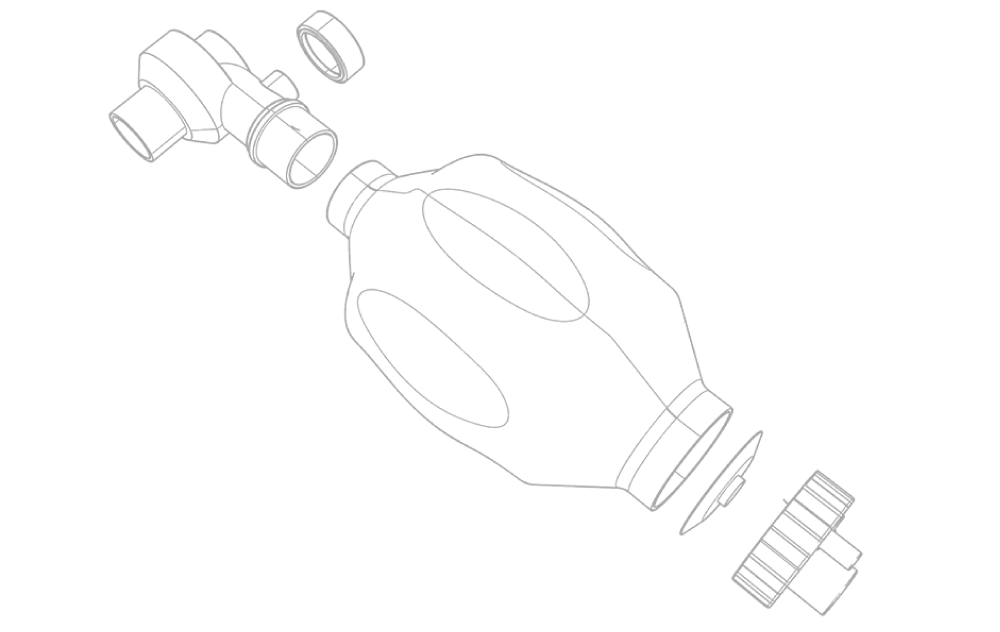

Manual resuscitators, such as the bag valve mask (BVM), are frequently used by medical professionals in emergency situations. There exists a large standing supply of them and they are easily manufactured. The automation of such devices will serve as an emergency alternative to the standard medical ventilator.

Download a model of the BVM here

Medical ventilators are complex machines—their manufacture require many hours of intensive labour. An automated BVM can preform the same basic function and even some of the more intricate ones—given the right electronics and software. The OpenLung can be mass produced at a faster rate than a standard medical ventilator—in saving lives time is of the essence.

Translating a manual resuscitator into a fully automated device that's sophisticated enough to serve as an alternative to standard mechanical ventilators was no small task. By making the design of such an open process, to which anyone from anywhere at anytime could contribute, the OpenLung moved from a hopeful thought to a concrete solution at unheard of speed.

The OpenLung came together via a novel decentrilised conceptualisation paradigm. Input from professionals all over the world was taken in and digested in real time. All aspects of the OpenLung were developed simultaneously and the iterations of development turned over at great speed.

The OpenLung is able to preform the same basic life saving functions as a standard medical ventilator. This is not to say that it is a replacement—it is an emergency device meant to ease the crisis of materials faced by hospitals all over the world. The device is an example of Just In Time Manufactuing—a decentralised design process centred on the availability of materials and ease of manufacture.

The OpenLung was designed with simplicity in mind. Due to potential supply chain disruptions and the fact that ventilators are needed internationally—the OpenLung brings together widely available materials via an easily replicated fabrication process. In the manufacture of mechanical components alternative materials, other than those suggested, may also be used should there be a supply problem in a given region.